In last week’s email I introduced the benefits of having not only an open mind, but the willingness to pursue new technology that can transform your business, and your bottom line.

Gary here . . . with a special guest. His story will blow you away.

For those owners in pursuit of newer, better products and methods of doing business, there is a huge payoff. And this payoff occurs in many different ways in a company. One way is the attraction and retention of employees who want to work for a company which is on the cutting edge of technology and delivers the highest quality service to their customers.

Long gone are the days of horse drawn wagon sprayers of the industry’s founders. But many owners still hang on to older methods and technology when newer options would serve them significantly better.

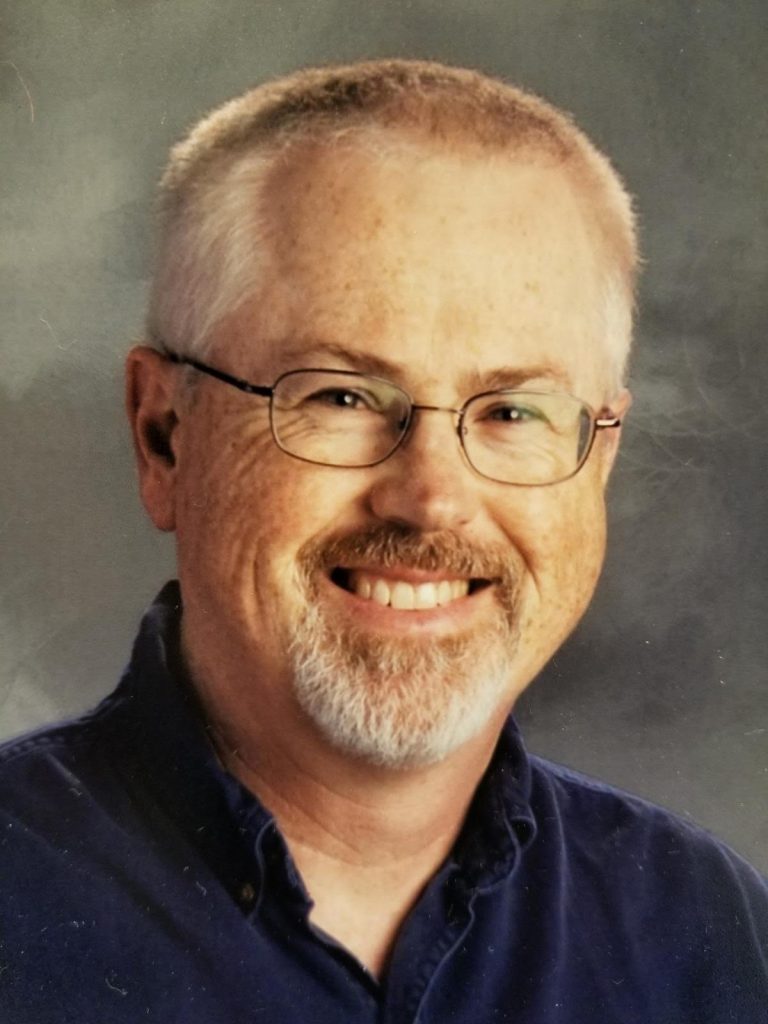

So, today it’s a case study from a 30+ year professional, an ISA member who has watched the transformation of the industry, not as a casual observer, but as one who has actually tested new products and application methods that we are using today.

Jim Dunkerley has a distinguished career in the industry, including a college professor teaching PHC topics, business owner and tree care industry consultant. There is very little Jim doesn’t know about taking care of trees, particularly the way it used to be done versus the way it can and should be done today. But I will let Jim speak for himself:

“Right after I left Chemlawn in 1987 with a solid PHC education from the original founders, I worked at Buckeye Landscape managing their Tree/Shrub care division. Buckeye was set up the old school way: calendar-based application rounds, zero inspections, heavy use of pesticides at full rates, and no biorational controls of any kind.

After one season of that, I set up a full IPM program based on a one-year trial I had used at Chemlawn, which they had discarded before giving it the opportunity to prove itself. I saw the potential of this dramatically different approach to plant health care that other companies were not using. It was called Integrated Plant Management.

I created a complete business plan that focused on the many benefits I anticipated, including lower labor cost, less pesticide use and better control. None of which we were achieving with our legacy program.

After outlining the comprehensive program to the Buckeye management team, they agreed to use the program with about one third of our customer list to test out what I wanted to implement.

The program consisted of the following:

- Inspect properties every 2 weeks for pests from April to September (about 11 visits).

- Treat only pest infestations.

- Preventative applications were allowed if the plants had a history of or predisposition to a pest.

- Pesticide applications were targeted to the affected plants only.

- Cover sprays were not allowed so that natural beneficial biology could have a sanctuary.

- Pesticides were used at the lower end of the rate limits.

After one season of the program, the results were so good that the owner was convinced that we should use it on all of our properties. As expected for the first year, labor cost stayed the same. But without any change in pricing, profits increased 10-12% due to reduced chemical usage.

But what happened next was way beyond my most optimistic expectations.

After five years we had achieved about an 80% reduction in labor expense and pesticide usage along with superior pest control. Since we were on the properties a lot more, we caught pest issues before they became bad. Also, inspections went about 5 times faster than cover sprays so we could provide season long control for the same price as a few cover sprays. As the years progressed, pest incidences fell to nearly zero, partly due to the increase in natural predator populations that we hadn’t killed with cover sprays. All of this resulted in further decreases in labor and chemical expenses.

Profit margins increased, exceeded 50%, although customer pricing stayed the same. Customer retention was phenomenal, only losing people that moved. Letters acclaiming the benefits of the program came in regularly with glowing comments about our program, which was universally preferred over standard PHC programs.

Customers paid a monthly retainer for six months from April to September. They understood that they were no longer paying for a disease management program with a certain number of applications. They were paying for a health maintenance program that required constant vigilance that dramatically reduced the amount of toxic chemical exposure to their families. This provided exceptional health for their trees and shrubs and they were ecstatic.

I learned a very valuable and lifelong lesson from this experience 30 years ago. Subsequently, if I heard of a new product coming on the market, or a new application method that would be more efficient, I would volunteer to do the testing. I was always looking for better products and better methods and still do to this day.

Next week, Gary is letting me share another story about one of my product testing experiences and the dramatic way it has changed the industry. I hope you’ll be back next week.”

Over 30 years ago Jim created a Win, Win, Win program in every possible way imaginable –

- Greater, more sustainable health for trees and shrubs

- Less toxicity on the property (and neighboring properties)

- Greater profitability for the company due to lower labor and chemical costs.

Jim can do this for your company and your customers also.

Engaging Jim Dunkerley as a consultant could be the best investment you ever make. His program is easy to implement and remarkably affordable. Call Jim today at 614-468-8745 or email him at JDunkerley@yahoo.com.